INDEX CNC multi-spindle machines: More productive

with 8 spindles!

Designed to meet precise user requirements

Machine highlights

Your benefits

- Highly-dynamic slide with sliding guide (X-axis)

- Non-wearing Z-axis dueto quills with hydrostatic support

- Front-opening machine for bar machining

- Chuck part machining with loading and unloading by robots

- Directed part discharge through linear handling

- Extremely fast swiveling synchronous spindles with C-axis

- Swing arm is locked by three-piece Hirth coupling in machining position, ensuring maximum rigidity

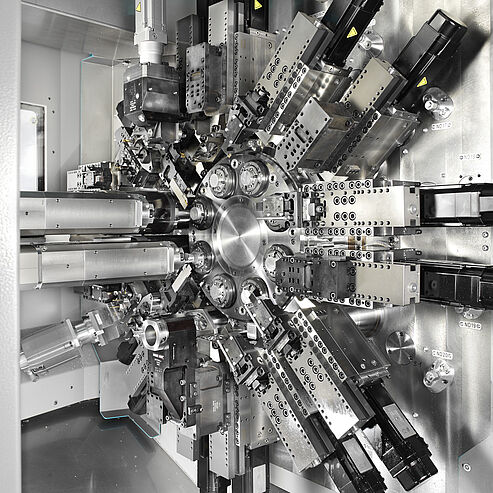

MS40-8 im focus

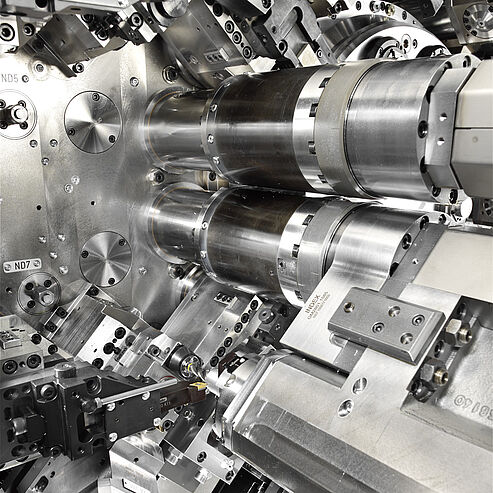

The thermostable spindle

Our trade mark –

the spindle drum

The compact spindle drum ensures maximum precision in each position through the use of a three-piece Hirth coupling. The basis is composed of 8 fluid-cooled motorized spindles integrated in the spindle drum. Infinitely variable speed control, (high dynamics) compact design,maintenance-free and the latest synchronous drive technology, as a guarantee for high-precision workpieces.

Independent speeds

During machining, the optimal speed, which can still be varied during cutting, can always be programmed for each spindle position and each cutting edge of the tool. The result is better chipping, maximum surface quality, short part production times, and longer tool service life. You can also machine high-strength materials that up to now were hardly suitable for multi-spindle machines. It is also possible to make speed changes during drum indexing, thus avoiding any additional secondary processing times.

Machine configuration

Full extension

- 14 tool carriers with 1, 2 or 3 axes

- Back-drilling slide with 7 tools thereof max. 4 driven for face machining

- Multiple occupancy of the slides possible

- Only the tool holder determines the machining direction (inside or outside)

- Cross machining with driven tools

Your benefit: Cycle time reduction due to 8 working spindles

Double 4-spindle

- 2 x 4 spindels for simultaneous machining of 2 workpieces

- Availability per workpiece: 6 x X/Z-slides, 1 x synchronous spindle, 1 x part-off tool with back drilling tools, 1 x back-drilling slide X-NC, 1 x back-drilling slide X/Z-NC

- Drum circuit: 3 x 90°= 270°(2 "maschines")

- Multiple occupancy of the slides possible

Your benefit:Additional cycle time reduction due to simultaneous manufacturing of 2 workpieces

"Versatility is the strength of the MS40-8. Whether complex parts or manufacturing methods are involved - anything is possible."

More than just turning

INDEX CNC multi-spindle machines with live tools, C-axis, and Y-axis give you access to entirely new processes, such as: Off-center drilling and thread cutting, inclined drilling, cross drilling, contour milling, hobbing (tooth cutting), polygon turning.

Handling of workpieces

Linear shuttle with intermediate gripper for directed parts removal from spindle position 8

Very rapid, position-oriented removal by a linear and rotary motion. The workpiece is transferred first from the synchronous spindle to the intermediate gripper. The linear shuttle then takes the workpiece from the intermediate gripper and passes it to the external handling system. This process takes place during secondary processing time.

Directed parts removal from synchronous spindle onto the internal conveyor belt

Axially-directed discharge by gripper and linear cylinder from the synchronous spindle in position 8 or 7 and 8 to the internal convey or belt for parts that may not be ejected.

Parts feed and discharge by 6-axis robot

The workpiece handling system for chuck parts and bar segments can be used for 8-spindle machining with and without synchronous spindle, as well as for double 4-spindle machining.

A variant

4x OP10 (first side) and

4x OP20 (second side) with external turning station is also possible.

3-axis linear shuttle for directed parts removal from the synchronous spindle

Damage-free and position-oriented delivery of components from the synchronous spindle in position 8 or 7 and 8 to the external handling system at the front of the machine. All 3 axes of the machine-integrated handling system are NC-controlled.