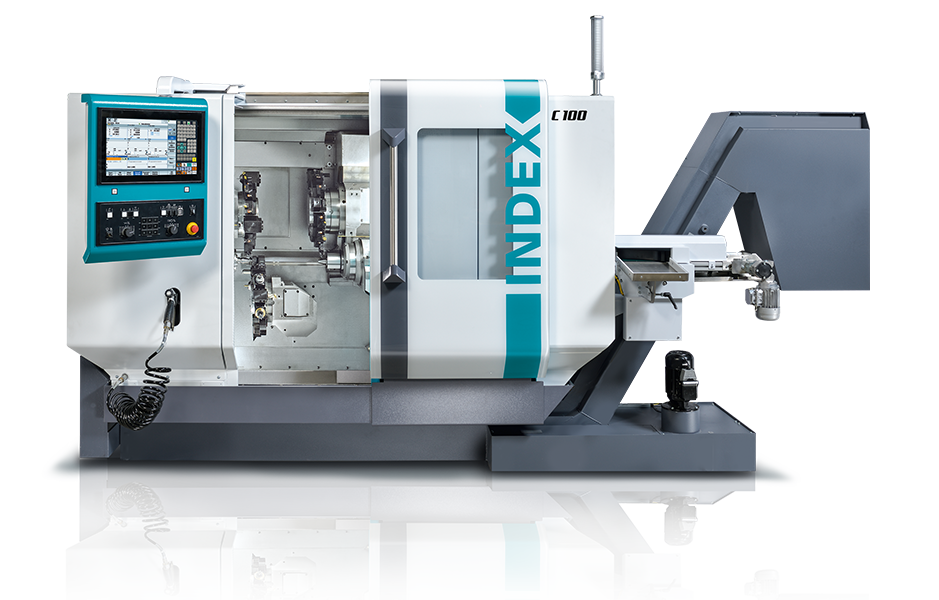

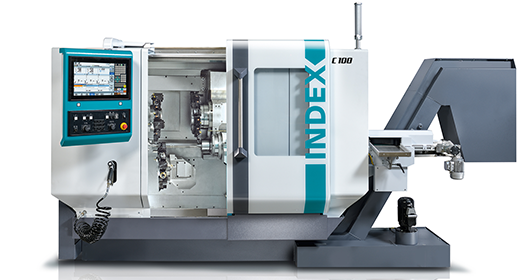

Automatic turning machine – for faster machining

Ideal for bar stock machining and complex workpieces.

Machine highlights

Your benefits

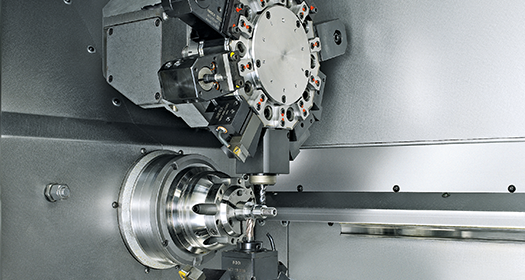

- Simultaneous machining using 2 or 3 turrets

- High acceleration (1g) and high rapid traverses (60 m/min)

- Workpiece carrier with Y-axis available on main and counter spindles

- 2 powerful motor spindles of identical design

- Very good vibration damping due to INDEX SingleSlide

- Maximum parts variety through 3 turrets and 42 tools

- Siemens S840D sl (18.5” touch screen) or Fanuc 31i-B control (15” touch screen) offers economic and productive solutions at any time

- Already included: the operating system iXpanel - i4.0 ready

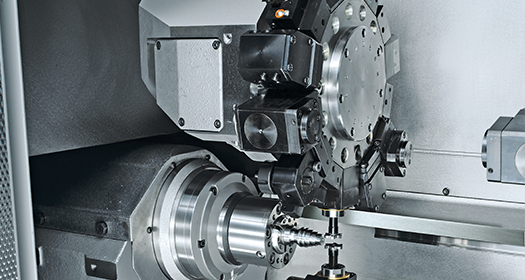

C100 in focus

Working space INDEX C100

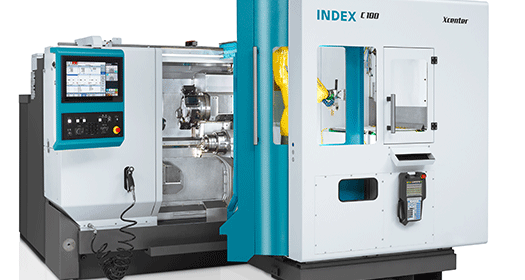

iXcenter robot cell

Intelligent automation – even more flexibility and efficiency

With the optional robotic cell iXcenter, blanks and/or finished parts can be supplied and discharged quickly, safely and flexibly. The robot cell is integrated ergonomically into the machine. It can be moved easily to the right during the setup process, allowing unobstructed access to the work area. During production, the iXcenter is fixed in front of the machine’s work area. The robot then accesses the work area via the sliding guard of the machine, which opens automatically behind the robot cell.

Simply good handling of blanks and finished parts

- Space-saving vertical storage with up to 22 pallets stacked up

- Pallet size 600 x 400 mm

- Minimal pallet height 25.4 mm

- Pallets with blanks are loaded at the top, pallets with finished parts are removed at the bottom – at any time without interrupting production

- The pallet is pulled in and out by the robot

- Easy macro-programming

Using more potentials

Subsequent processes such as cleaning, measuring, deburring, etc. can be integrated in the robot cell

Ready to Go

- 6-axis robot for 7.5 kg payload with integrated gripper control

- Double gripper included in the standard

- 22 pallets (without workpiece-specific inlays) are included in the standard

- Easy in-house relocation